3D Printing Services

SLA PrintingStereolithography, or SLA, is a process by which photopolymer resin is laser-cured layer by layer from a vat of liquid resin. It provides outstanding detail and dimensional accuracy (down to 0.025mm) for applications such as jewelry & accessories (using castable resin), medical devices, assemblies, snap parts & living hinges, functional parts & prototypes, short-run production, etc.

Materials include standard Clear, Black, White, Gray (custom colors available) as well as Castable, Tough, Flexible, High-Temp, Elastic, Durable (similar mechanical characteristics as polypropylene), and more. |

FDM PrintingForced Deposition Modeling, or FDM, is a means of building objects layer by layer with heated & extruded polymer. While it doesn't deliver the same fine detail and finish as SLA, it has a larger build volume and wider material/color range. In addition, there are a variety of post-print treatments available that provide glossy, metallic, patina, and other effects.

Materials include PLA (starch-based) and ABS in a wide color & transparency range, Nylon, Polypropylene, Carbon Filled, Glass Filled, Flexible, Tough, and other exotic materials, including metal-filled, wood-filled, etc. |

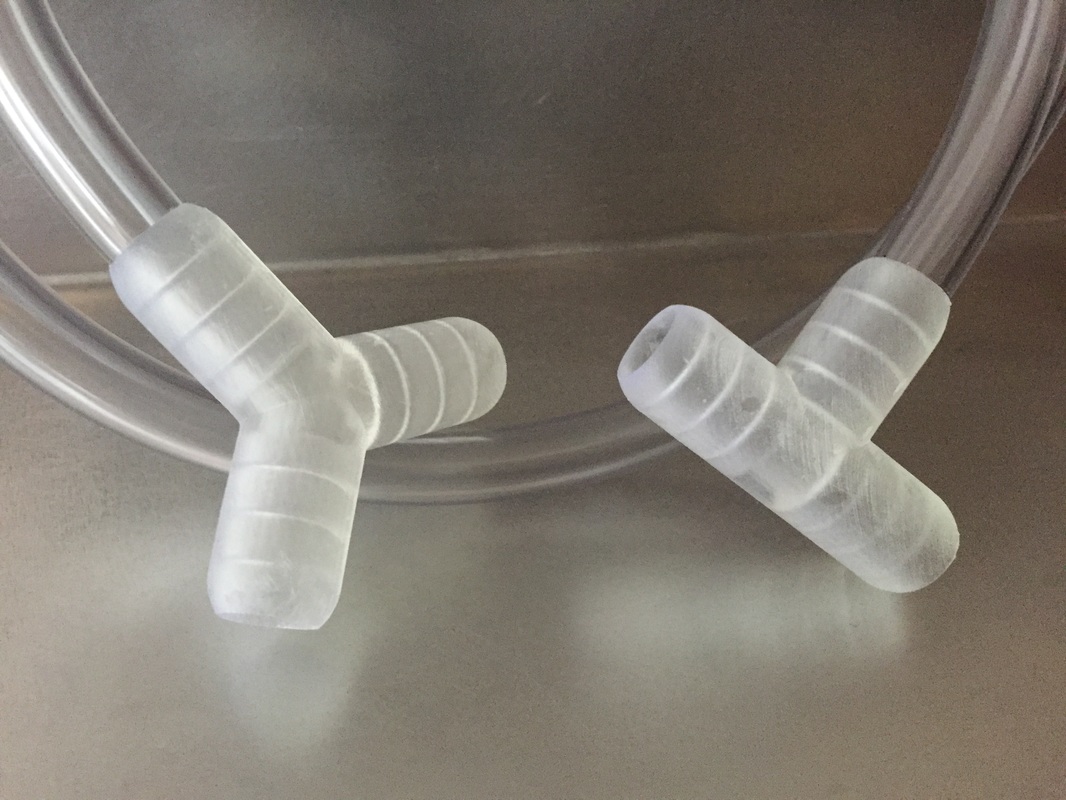

SLS PrintingSelective Laser Sintering, or SLS, fuses successive layers of polymer powder together to build a solid object.

This process is especially well suited for functional and durable products or prototypes in materials such as Nylon. |